A fluidized bed is a thermal cleaning method used to remove any dirt like paint, grease, rubber, plastic etc. From metal parts. The bed is a metal construction in which calibrated sand is heated to 600 degrees until it becomes liquid. With a special technology, the sand acts like a liquid in a whirpool and cleans any metal part which is lowered in the liquidized sand. The method is entirely non-invasive and does not affect the metal part at all. All that is left after cleaning, is a super clean metal part, and some dust in a bucket.

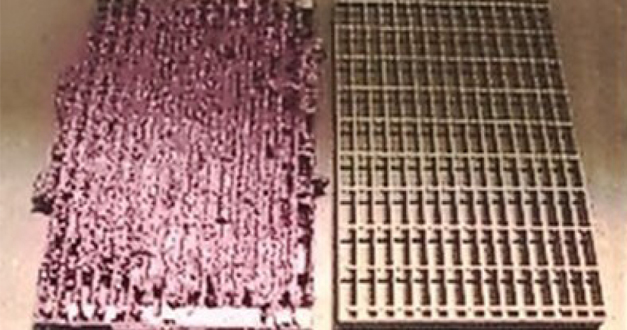

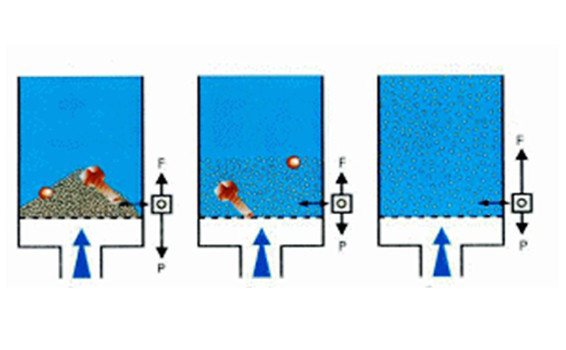

Fig. 1

A fluid bed basically consists of a reactor filled with calibrated quartz sand.

At the bottom of the reactor gas and air is injected.

A specific flow is generated and the sand starts to fluidise, as seen in figure 1.

This allows the sand to behave lake a liquid and take on many of the same properties.

Parts heavier than the sand particles will sink to the bottom, parts lighter than te quartz sand are blown out of the reactor.

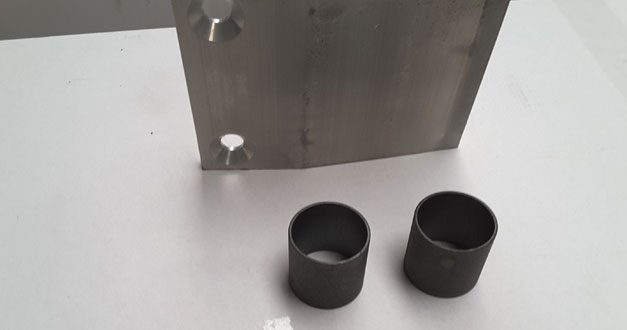

This principle is illustrated in Fig. 2

Fig. 2

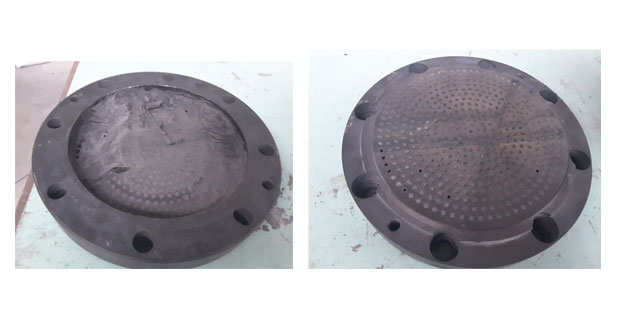

Industrial applications of our technology are vast:

Removal off all paints and plastics , adhesive bonding

Removal of casting sands

Waste management: Denuding rubbers Recycling of metals

To implement these applications in your business provides an advantage in both: cost-efficiency and enviromental impact.